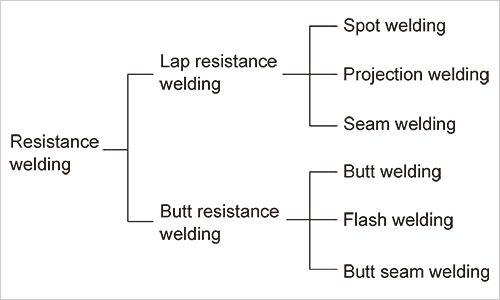

Resistance welding

Resistance welding

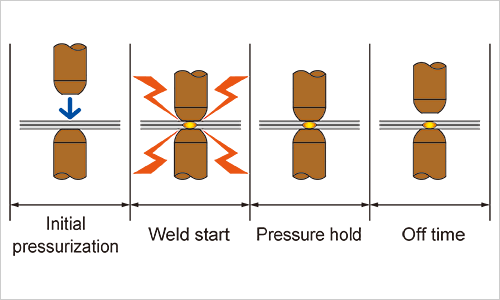

Three welding conditions of resistance welding

Welding current, weld time, and welding force are called three welding conditions.

These conditions are closely related to each other. So, it is important to combine the conditions properly.

1. Welding current: The current flowing in the welding material

2. Weld time: The time when the welding current flows

3. Welding force: The applied force to the work piece

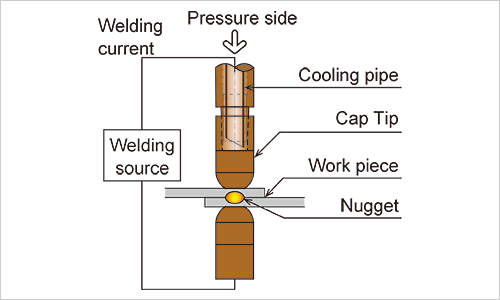

Also, there is a tip diameter of the electrode. It is an influential factor to nugget diameter.

Spot welding

Spot welding

It forms the melting part and joins it to the junction of the works, sandwiching two(or more than two) overlapped work pieces between the electrodes, flowing a large current in the pressurizing state, keeping the balance well between the heat generated of a work piece and the heat conduction to the electrode as well as a work piece.

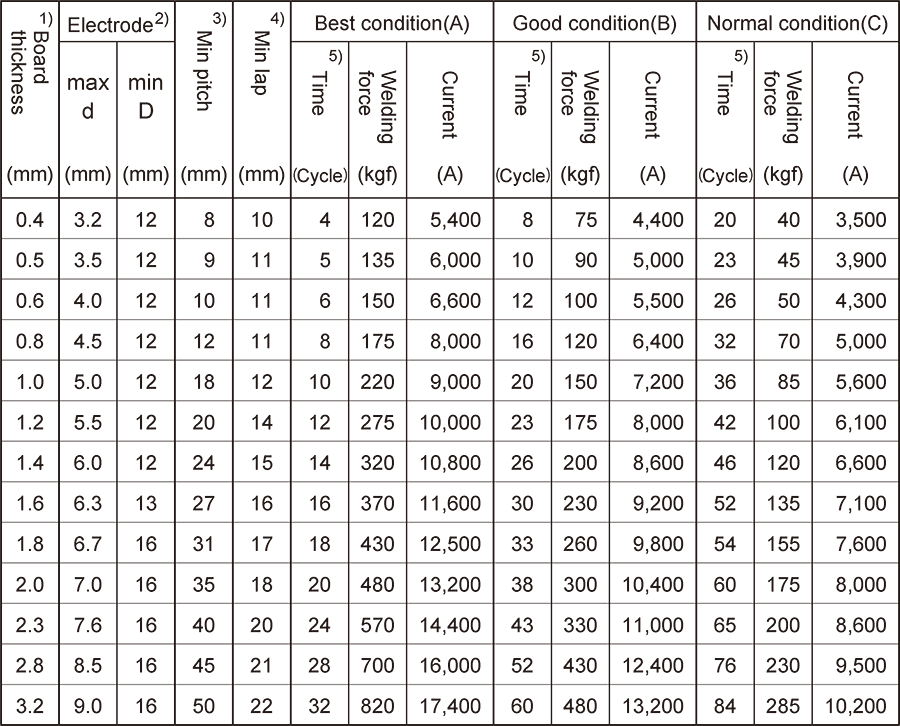

Recommendation Spot Welding Condition

Resistance Welder Manufacturer’s Association Abbreviation RWMA

RWMA Recommendation Spot Welding Condition List

- The work piece shown on this list is only two overlapped by the same board thickness, is a mild steel plate whose tensile strength corresponds to 30~32kgf/㎜2, after processing hot rolling, acid pickling, and slightly oiling. The surface condition in welding should be clean without black, grease, oxide, paint, and dust.

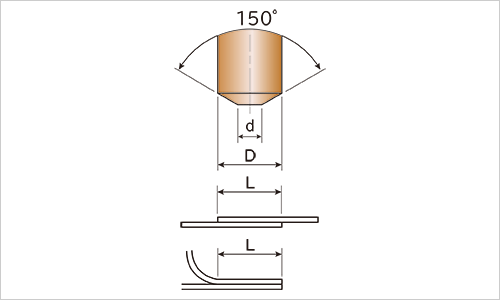

- The electrode material shall be class 2 of RWMA( conductivity 75%, Rockwell hardness B75).The tip shape is as in the right figure. The allowance of d is ±0.4mm.

- The minimum pitch means the ignorable limit of shunt effect by next welding point. In other word, it needs to be adjusted to proper current value, considering shunt effect, in case of welding a work piece with the below pitch than this value.

- The minimum lap is L of the right figure. If the L is below this value, the strength is lowered, and a strain occurs.

- Weld time means a cycle number in a power supply frequency of 60Hz.

So, the weld time of 10 cycles is one sixth second. In case of welding a work piece in a power supply of 50Hz, weld time should be set to five sixth of the value of the list.

This reference is shown only as a guide. Welding condition will change due to a work piece, welding machine, and the tip shape of electrode tip. Please confirm them in advance.